Thought I'd join the community and share my build and enjoy what everyone else is up to. I currently have far too many cars and projects, but amongst them is a 1999 V70 Estate and a 2006 C70 convertible. Shamelessly I'll admit, the C70 was purchased to score the engine as I bought the V70 with an engine that had been so overheated it took my block-and-tackle to remove the cylinder head....the entinte engine was distorted. Anyways the C70 has only 117,000km's with full history and seemed a great donor for the mechanical side of things (if anyone needs C70 parts Just let me know!)

Won't insert a photo of the cars...we all know what they look like!

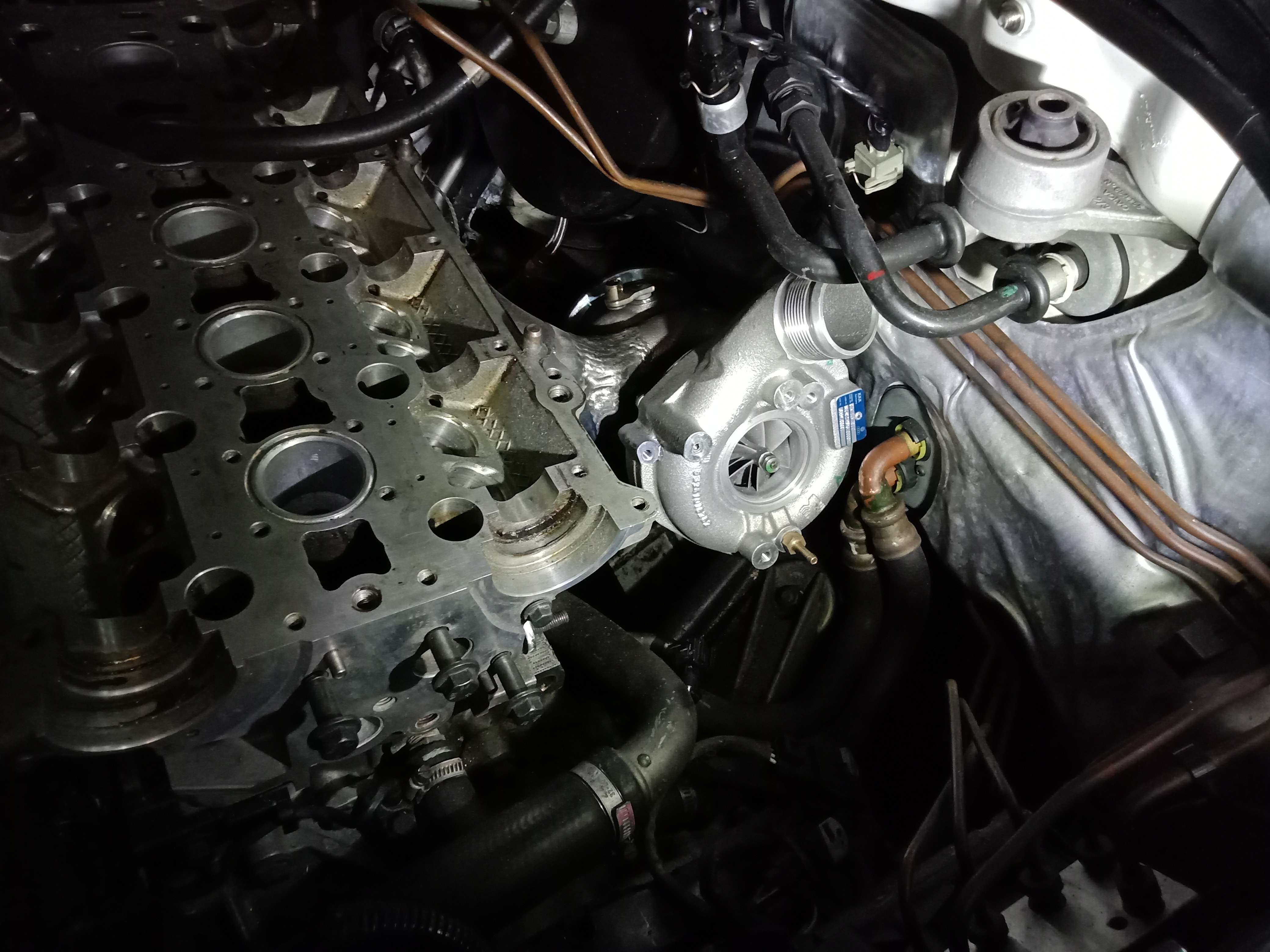

For now I am still zipping around in the C70 and using it as a test-bed while I prepare the V70. In April i bought a new 18T billet turbo from GCG and it runs beautifully. Certainly picked up considerable power. It came with a 7cm ported turbine housing which really freed-up the upper rev range with just a bit of lag. As my goals are beyond the power level I intend to reach I guess I'll sell the turbo if someone is interested. The car has done about 1,000km since installed.

So, I've started developing several components. Firstly the exhaust manifold. It is not finished yet as I have just been too busy with work for clients (they always come first) but I have built a short-runner tubular manifold with a true collector. This is quite a big step forward compared to the conventional "Jap" manifold and the other iterations. yes, it is true that you can just bump up the boost a few psi to make the same power, but the implication is higher EGT's, higher IAT's and an overall inefficient engine. With a proper tubular manifold and collector the engine is more efficient so will make power easier. Being a short runner manifold, the response will still be excellent. Here is the manifold as it sits now, just needing another 3 or 4 hours to reach completion

I've also been developing the intake manifold. The original manifold has, in my opinion and in comparison with modern engines, very small diameter intake runners and bellmouths into the runners. So in my spare time I have cut open the manifold, put a 6 degree chamfer cut into the runners and increased the bellmouth diameter. Somehow I deleted the photo of this stage...not happy. I also deshrouded the entrance into the plenum after the throttle body; it is far from ideal from factory. From there I also increased plenum capacity by an additional 750cc. The runners have been port-matched slightly smaller than the head

Will continue the development and keep updated :)