AJ's Hilux LN46

- Edited

I reckon that 'oem boxed GMB' is different to 'retail/consumer GMB'. At the very least, this appears to be the case on some of their offerings.

If not, Adrad do a core and end tanks but not an assembled radiator.

- Edited

The original radiator tanks and brackets have been fitted to a new Adrad core. New Tridon "high flow" thermostat fitted. Not sure if more flow through the thermostat is actually a good thing, however a mate is running one without issues. I'm really hoping this along with injectors will solve it getting hot under load.

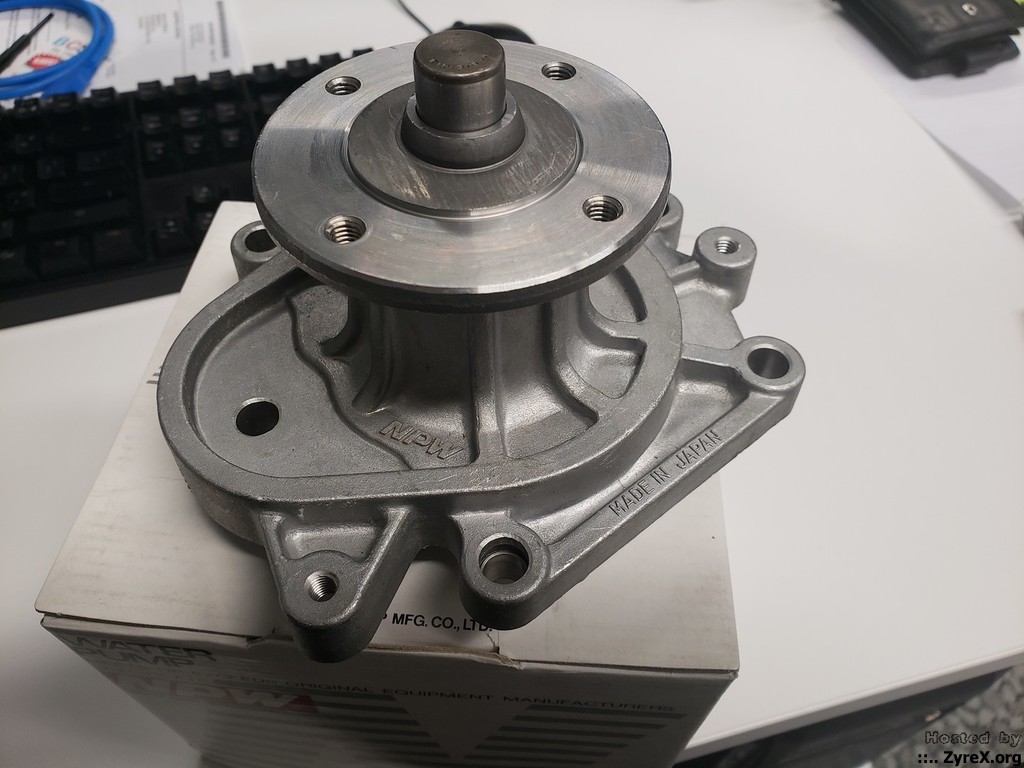

This arrived today:

Battery tie down bracket was full of corrosion, so I've peeled off the plastic coating and cleaned it up with a wire wheel. Will treat with rust converter and paint.

Current list of jobs to be done:

Set valve clearances

Paint or powder coat rocker cover

Fit sump

Rebuild or replace injectors

Test glow plugs, replace as necessary

Test viscous fan hub operation, adjust and refill if necessary

Remove LED light bar, I don't like the look of it and no longer need it

Find and fit a decent grille

Bend the winch control box bracket, I've never liked the 45 degree angle

Replace drag link ends

Replace swivel hub seals

Delete brake backing plates

Tidy up some wiring in the engine bay

G52 gearbox conversion

Turbo stuff

Drive it

I should do something about the brakes. They work well enough now, so I could probably leave them alone. The front brakes are 4 piston with solid rotors. I'm very tempted to upgrade to the slightly larger LN106 4 piston calipers and vented rotors. Not too sure what (if anything) needs to be done with the master cylinder to make that work.

The hand brake doesn't work too well either. LN106 rear drums may fix this issue, and in theory would remove any doubt about which master cylinder to use. Assuming hand brake cables would have to be custom made.

Turbo setup will most likely be the TF035 from the Foz GT parts car on a Rock Solid Engineering manifold, simple crossover pipe, and 2.5" downpipe into the current exhaust, with a rear muffler delete.

Test fitted the turbo manifold. Anyone selling a 13C?

DauntlessTest fitted the turbo manifold. Anyone selling a 13C?

https://zyrex.org/gallery/d/145901-4/20191203_223405.jpg

I think i got at least one good one you can just have

Philia_Bearhttps://ozvolvo.org/discussion/comment/169707#Comment_169707

I think i got at least one good one you can just have

That would be excellent! I should be passing through on Sunday or Monday

I found the ideal manifold design to suit the Subaru TF035/TD04, but unfortunately they're no longer made. I'm tempted to have a go at making one.

Design looks pretty simple to replicate, though it would still take a lot longer to make than you would think.

If you really want to use a subaru turbo why not use an adapter to the manifold you have?

https://rover.ebay.com/rover/0/0/0?mpre=https%3A%2F%2Fwww.ebay.com.au%2Fulk%2Fitm%2F133279037129

Yeah, it would take forever to make without a jig and the right tools.

Unfortunately there's very little clearance to the brake master cylinder and lines, so even using a thin adaptor for the 13C will mean machining down the manifold flange and modifying brake lines.

To me its very basically done and in my pipe fitting experience , gaining flow in industrial use and having to keep swirl and obstruction for metering etc , this is a shit design for gas flow. I see its compact but that mani would be very cheap or SHOULD be considering it is crappy.

Get the flanges , mock up an original mani to show where you want it to go in a jig and put the flanges on in place then run some bends and tube to fit with reasonable flow. Yes , takes a long time if you don't have piping experience. The difference of a novice and a pipe fitter is usually the job gets done , the novice gives up with tons of scrap....

Get a local to make you one , look online at welding sites , teach out to a Pipey.

- Edited

You're right, but it's still better than the standard manifold and the commonly available $550 fabricated manifold.

I doubt anyone would make one locally, and if they did it would be seriously expensive.

- Edited

May have got you the hard part, but that lets someone else build the rest...

https://www.ebay.com.au/itm/12mm-Toyota-2L-3L-5L-Exhaust-Manifold-Flange-Plate-Hilux-4-Runner-Diesel-Turbo-/323708464874It looks like that they're same across the L engines, so that should work...

https://www.ebay.com.au/itm/Toyota-Hilux-4Runner-2-0L-2-4L-2-8L-3L-Exhaust-Manifold-Gasket/264409946352?hash=item3d900f98f0:g:C7oAAOSwCDxdyfgHhttps://www.allfourx4.com.au/Inlet-Manifold-Gasket-Toyota-Hilux-4Runner-L-Series-Diesel-Engine-17177-54021

If it's just a log manifold, I can teach you how to either arc or mig it

Then we can make it to use a turblet from the t6 because spool!

I've made some purchases, if no real progress just yet.

16x8 -25 Black Bear wheels, need to organise paint. They'll be fitted with 265/75R16 BFG KM3s.

R150F gearbox from an LN130 Hilux Surf, bellhousing not shown. I'll probably sell everything except the bellhousing and buy an R151F from a 1KZ/1KD Hilux/Prado and use an adaptor kit to fit an RF1A gear driven transfer case from the LN106 spec G52 I have laying around.

- Edited

I ended up deciding on Toyota 045 Natural White.