So a while back I fitted a new oil pressure line, and the gauge still didn't move off zero. I replaced the gauge, same result. The oil line appeared to be perfectly clean on the gauge end, so I removed it to find this on the banjo end:

Poked a hole in that, cleaned out with brake cleaner, confirmed brake cleaner flows from one end to the other. Refitted and still no reading.

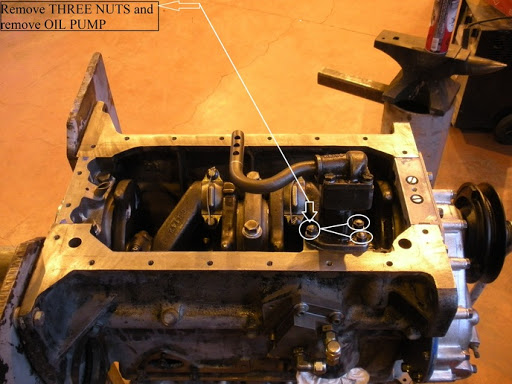

Removed the bolt and found nothing similar in my oil pressure test kit, so cranked the engine over with the bolt still removed. Oil does flow, but how much should I expect?