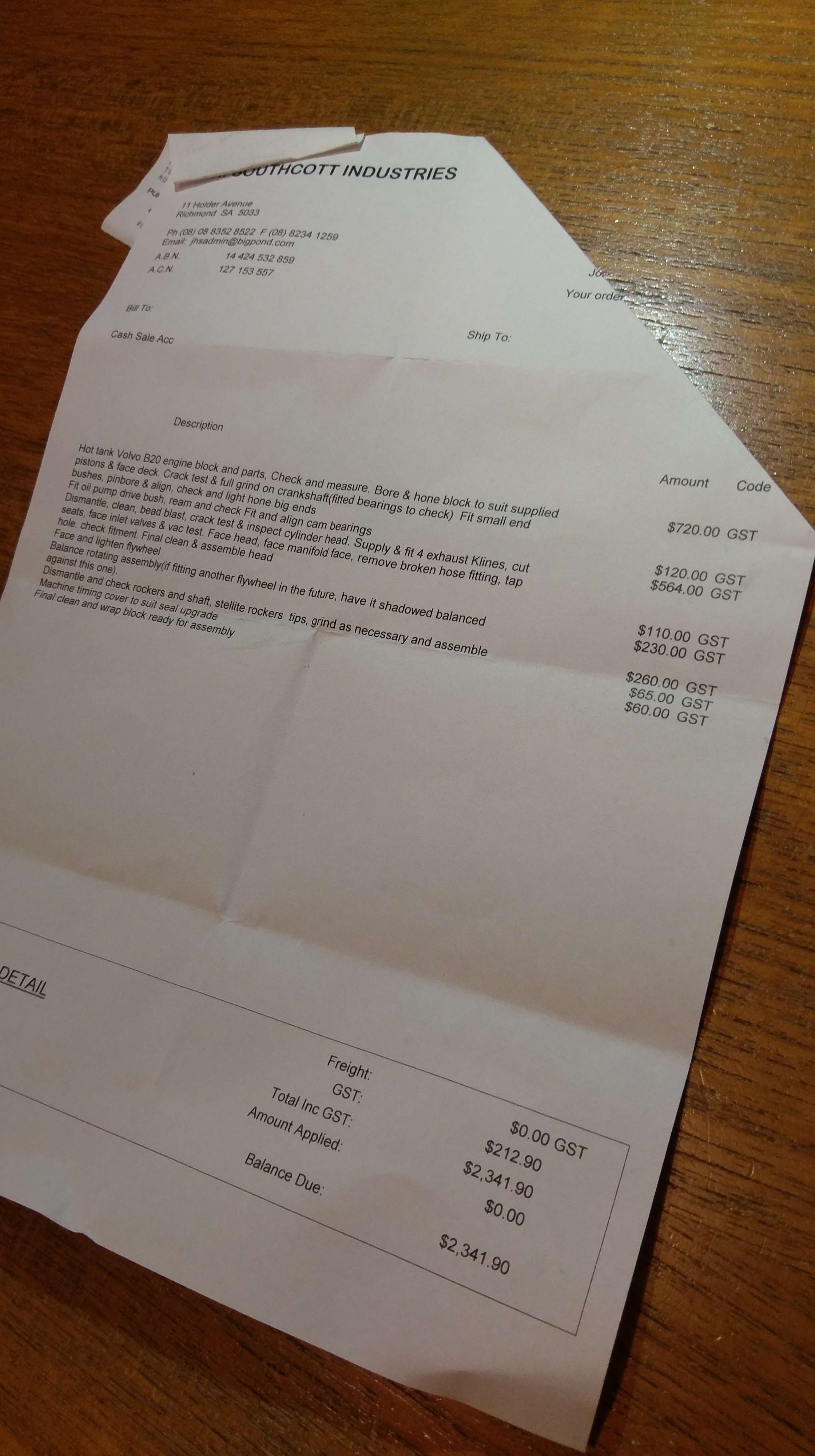

I got my parts back from the machine shop. Quite happy with the service. Took just over 2 weeks, but I did say there was no rush.

Today I cleaned up the garage a bit and started cleaning some of the yucky bits.

Not sure about the little parts washer yet. For about $200 for the washer and the proper solvent parts washer fluid I could buy a lot of the SCA degreaser spray cans.

The machining all looks really good, although I'm not sure what a "kline" is. I must call and ask. The balancing guys (sub contracted) had to really grind a lot of of the big ends to bring them down to match the lightest. I expect it will make a good improvement. Will try to take pics to show.